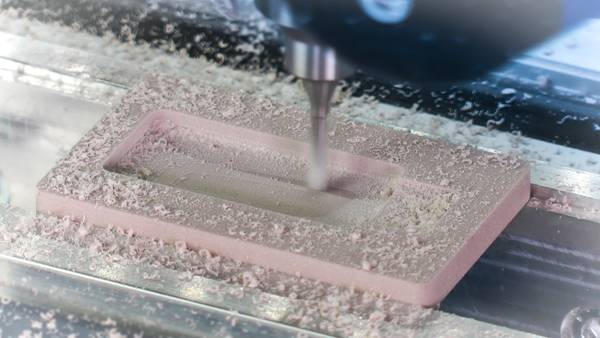

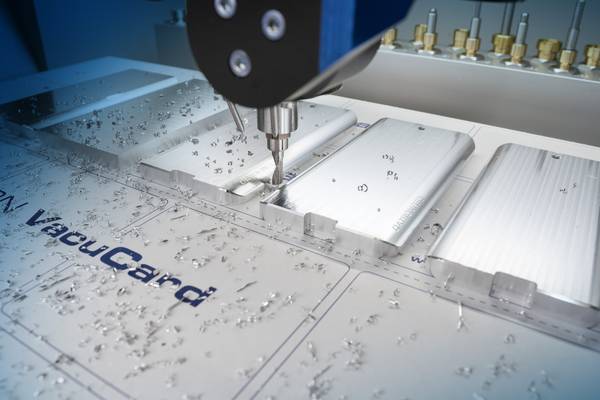

The new, ultra-compact high-speed milling machine DATRON neo (H 188 cm x W 80 cm x D 130 cm, 700 kg) turns out to be a true all-rounder for small batch production and prototyping. Due to its dynamics, it provides a high surface quality, intricate engraving when using small tools, and is ideal for a wide range of applications and millable materials. This makes DATRON neo a flexible machining solution for both conventional production environments and rapid prototyping labs.

While the ease-of-use makes DATRON neo a logical choice for easy entry into CNC and high-speed cutting (HSC) technology, advancements in its control software, DATRON next, distinguishes it as revolutionary. Based on the Plug-and-Play approach even inexperienced machinists get to easily control the 3-axis CNC milling machine due to its user-friendly software concept. Similar to using a smartphone with swiping gestures, the milling process becomes nearly as simple as 3D printing. Assistant functionalities and an integrated camera help the user to successfully start the milling process in just a few steps.

Self-explanatory icons and realistic 3D illustrations of tools and components facilitate quick identification of various functions and provide a positive user experience. The premiere advancement of DATRON neo technology is the combination of a camera in the working area controlled by a sensitive multi-touch display. This allows the user to easily locate and setup the work piece with swiping gestures which prevents the time-consuming manual entry of complex numerical data. In addition, the operator is given the opportunity to simulate the milling process in 3D in advance and can adjust details before actually milling. After super quick setup of the part, the user can rely on the proven high-speed DATRON milling quality.

Visually, the DATRON neo is also vanguard. Just before the official market launch the industrial milling solution received the red dot industrial design award 2016. With its straightforward and timeless design, this future-oriented, 3-axis milling machine offers ergonomic accessibility and was especially engineered to machine aluminum, nonferrous metals, wood, engineered plastics and composites. This fully equipped HSC milling machine fits through any standard door and therefore is ideally suited as an extremely space-saving manufacturing system in small run production and prototyping environments.

Experience the revolutionary DATRON neo at the AMB 2016 in Hall 7, booth A52. Our DATRON experts are looking forward to introducing you to this rock star among the compact milling machines.

About DATRON AG:

DATRON AG develops, produces and sells innovative CNC milling machines for the processing of future-oriented materials such as aluminum and composite materials, dental milling machines for the efficient processing of all common dental materials in dental laboratories, high-speed milling tools and high-performance dispensing machines for industrial sealing and bonding applications. With the help of latest technology, backed by numerous patents and the integration into a comprehensive service package, DATRON offers unique solutions.

DATRON machines are characterized by a high quality and efficiency at very low power consumption. DATRON systems, among others, are used in electrical engineering, metal, plastic and automotive industries, aviation and in dental technology. Over 2,000 machines customers, domestic and foreign, trust in the proven DATRON technology.

DATRON has been on a profitable growth path for years. Thus, sales of around EUR 42.6 million were achieved with more than 25 sales partner worldwide in 2015. Currently, DATRON employs around 240 People. The company has received many awards during recent years. The consulting firm Munich Strategy Group (MSG) ranks DATRON among the most innovative SMEs in Germany (DATRON achieved position 30), published in an independent study at the end of 2015, and further ranked DATRON as a TOP 100 company. Most recently DATRON AG received the "Customer Champion 2016" award at the end of April and the RedDot Industrial Design Award 2016 for the brand new industrial CNC milling machine DATRON neo.