Mühltal, 04.05.2017 - Contours, boreholes, and pockets without fractions, homogeneous surfaces, and precise milling details, as well as cramped working space conditions are one of the major challenges in prototyping labs and shops. In addition, the industry has a high degree of flexibility when processing a wide variety of materials, which is one of the most frequent requirements for a milling machine.

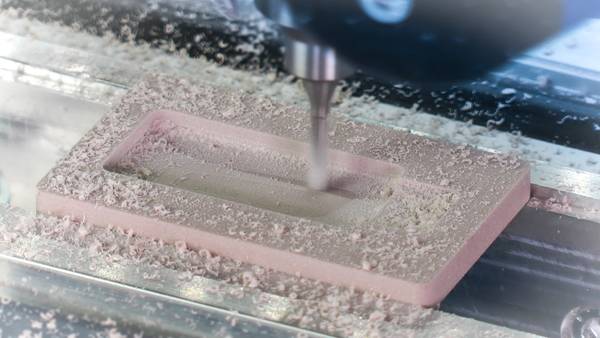

In the application example of a prototype component made of PU foam, DATRON neo, the latest milling machine from DATRON AG shows its versatility and convinces with results that do not require post-machining.

With the compact multi- talented machine, all functional surfaces such as profiles, radii, splines or threads can be implemented quickly with high-quality, so that prototypes are produced from the most varied materials in the same quality. The space-saving 3-axis manufacturing system (B 805 mm X T 1290 mm X H 1880 mm) also allows precise machining of tough materials, and optimized 3D and planar surfaces.